Hazard Monitoring for Grain Elevators

A Modern and dynamic safety monitoring system.

M-Jet Hazard Monitoring Devices

Motion Controller Options

Motion controllers are specially engineered to control the constant speed of a rotative shaft. It is frequently installed on buckets’ elevators, chain conveyors, mixers, locks, etc.

The VIGIRO® IP26 includes a pulses ometer which is either connected on a preset machine or on an independent security module to ident the nominal pulses’ frequency at the outlet.

The VIGIRO® SV26 was engineered to control the constant speed of a rotative shaft to detect any fault in the case of a dangerous under speed.

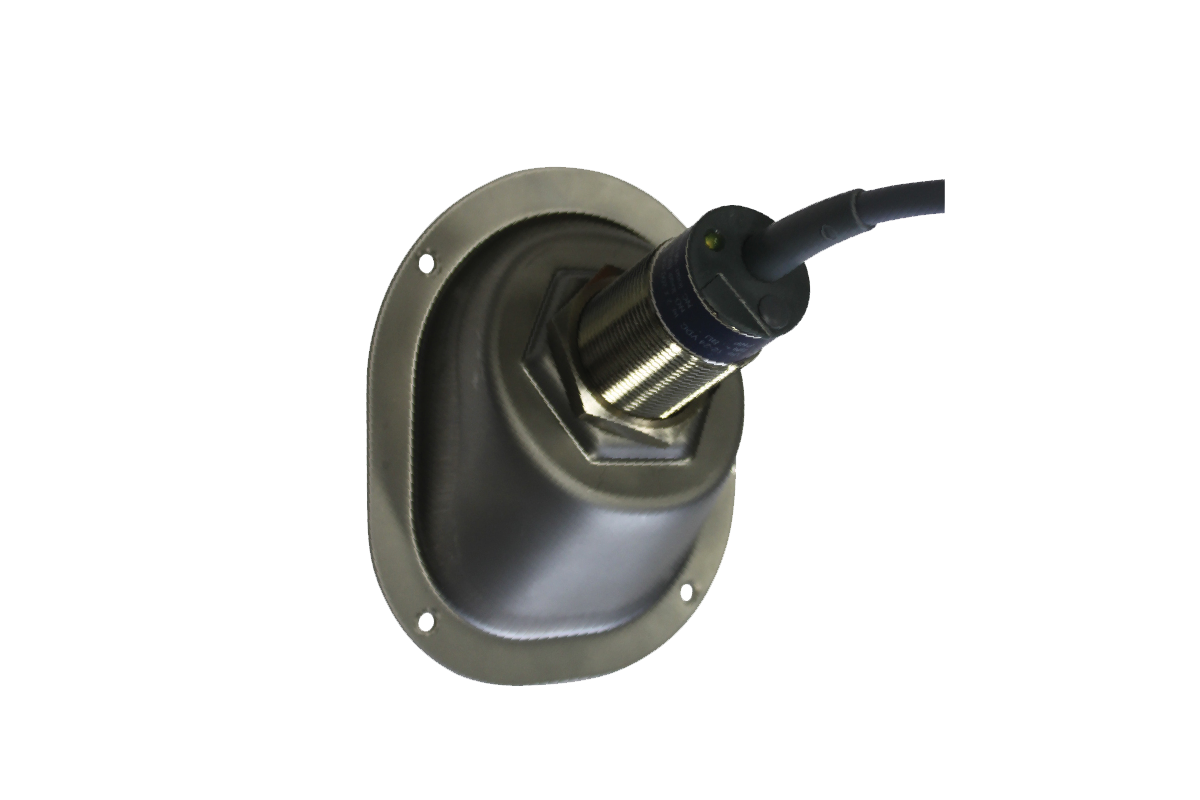

Belt Alignment Systems

The VIGIBELT® TOUCH is a lateral movement sensor that detects run-out of elevator belts or conveyor belts, and at the same time the run-out of the lift pulley. It reacts to the pressure of the belt coming into contact with the front face of the sensor.

The VIGIBELT CDM80C® is an elevator belt alignment system which has to be placed on an elevator in order to avoid any friction between the belt and the inner sides of the elevator’s leg.

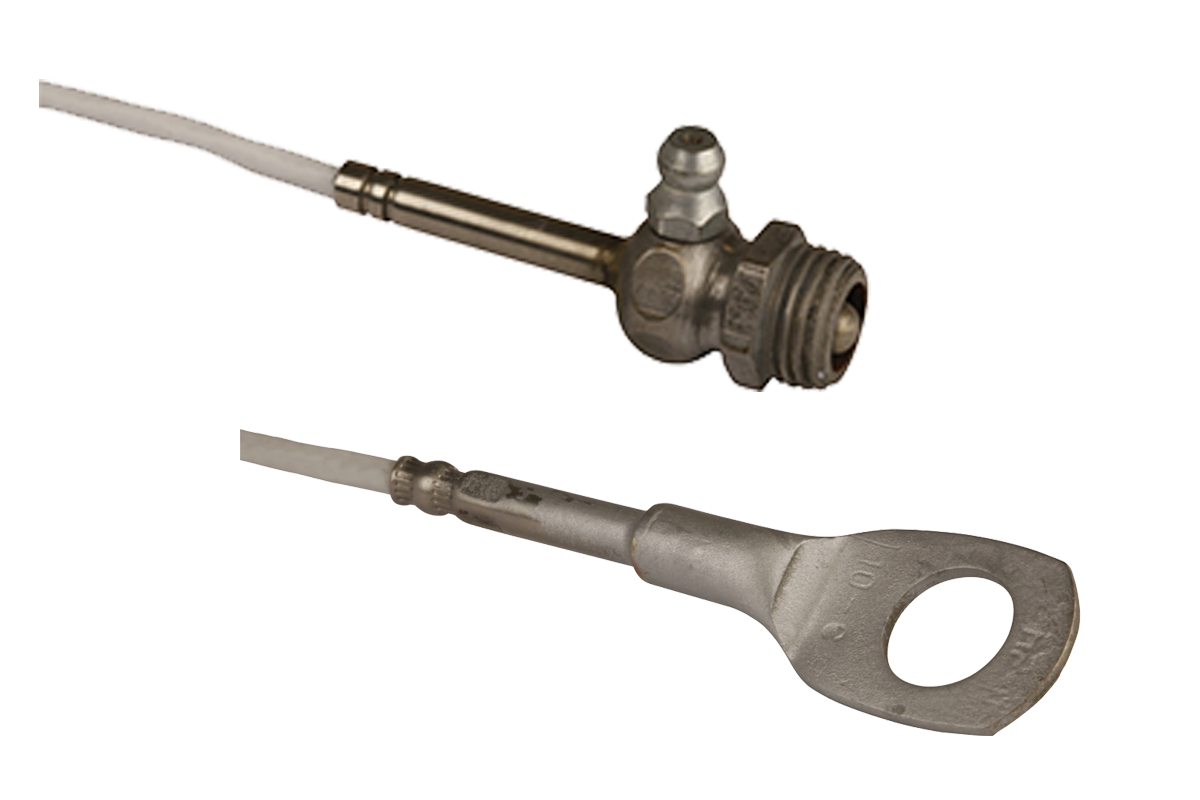

Bearing Temperature Sensors

Two options are available for the VIGITHERM Bearing Temperature Sensors. Both are PT 100 Class B ATEX Certified sensors that can be connected directly to a central control area or to the hazard monitor M-JET+.

The VIGITHERM GST 100 LG is rated for ATEX Zone 21, Dust.

The VIGITHERM GST 100 HX is rated for ATEX Zone 20, Continuous Dust.